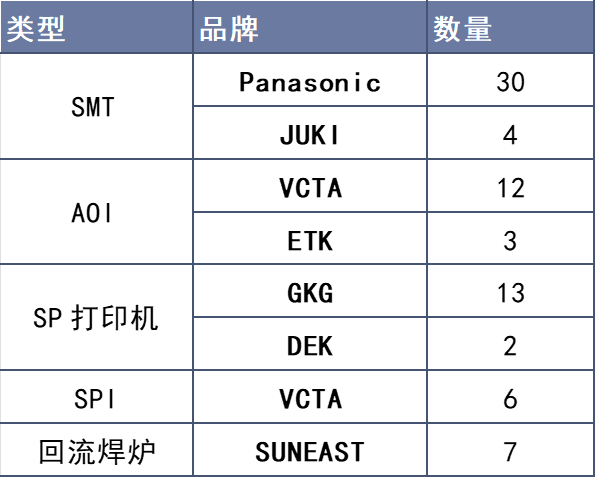

SMT

Guide

KingChuang 2019Service and Product Guide booklet, easy to read and choose all the services you need to provide

Download《KingChuang the 2019 Guide》

Download《KingChuang the 2019 Guide》

-

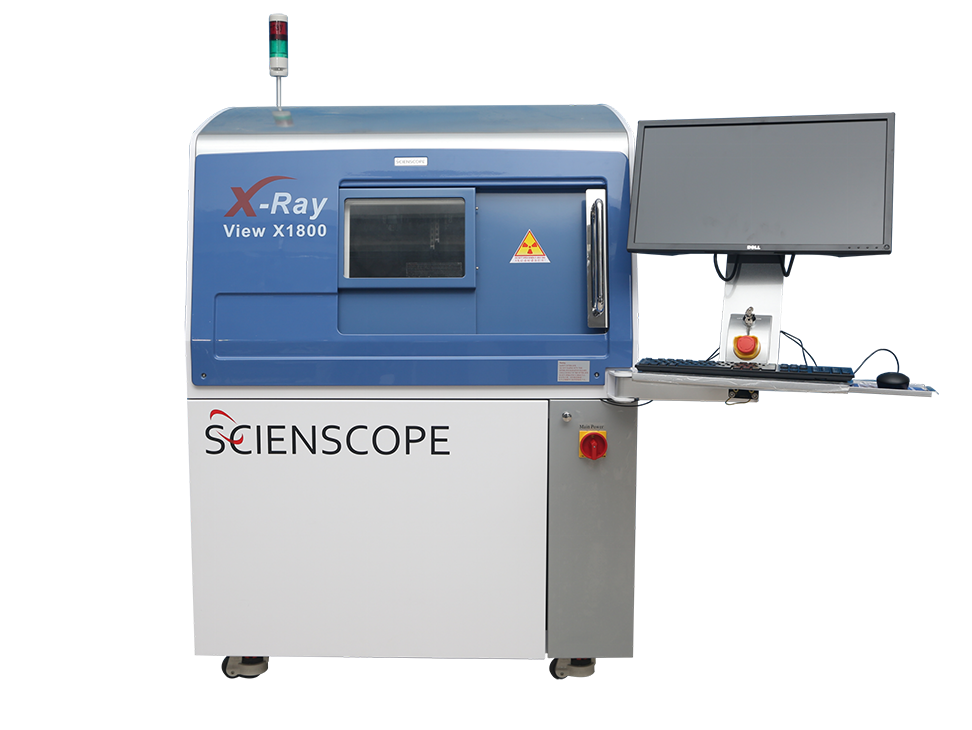

X-Ray X-ray detector

-

Shansi X-RAY testing equipment

-

Panasonic NPM

-

GKG automatic solder paste printing machine

-

device

-

workshop

-

AXC-800III

-

Panasonic NPM placement machine

-

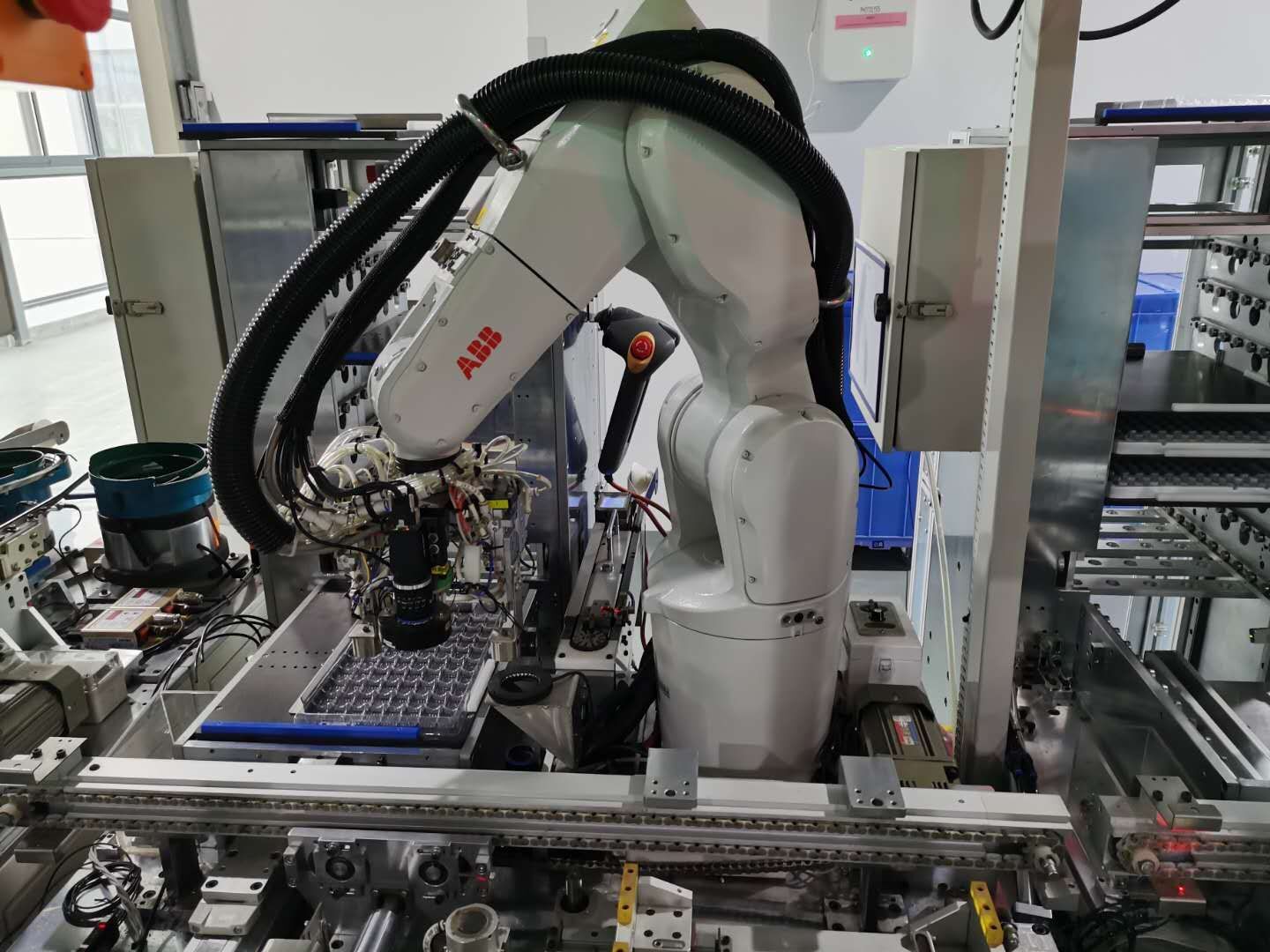

DIP workshop equipment

-

DIP workshop

-

DIP workshop

-

COB solid crystal machine

-

Microscopic examination

-

COB sealing machine

-

Tunnel furnace